El sistema de bomba contra incendios Purity PEJ está diseñado para clientes que buscan una solución de alta calidad y fácil de usar, proveniente de un fabricante de bombas contra incendios de confianza en China. Gracias a su diseño operativo simplificado, la unidad PEJ no requiere ensamblaje adicional, lo que permite una instalación y puesta en marcha rápidas, ideal para proyectos urgentes y situaciones de emergencia.

Para satisfacer las exigencias de eficiencia actuales, el sistema PEJ combina una bomba jockey de bajo consumo con una bomba contra incendios eléctrica de alta potencia, lo que proporciona un ahorro energético excepcional y mantiene una presión estable. Esta configuración inteligente reduce significativamente el consumo eléctrico, convirtiendo al PEJ en una excelente opción para promotores, constructores y distribuidores que buscan bombas contra incendios que ofrezcan rendimiento y una buena relación calidad-precio.

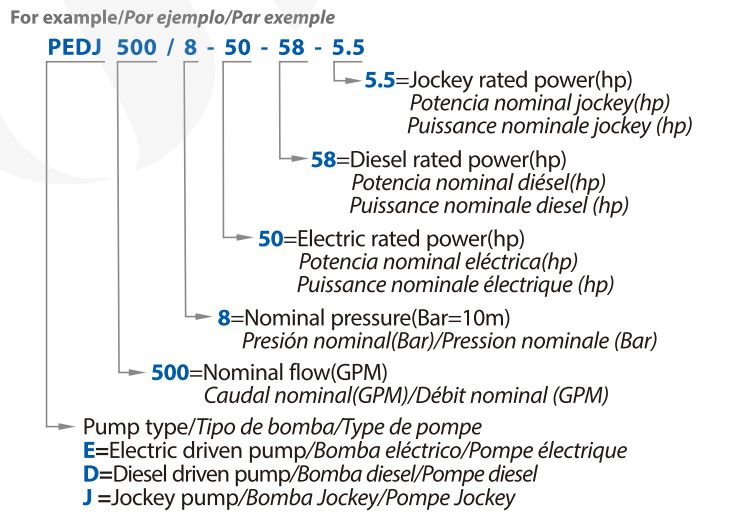

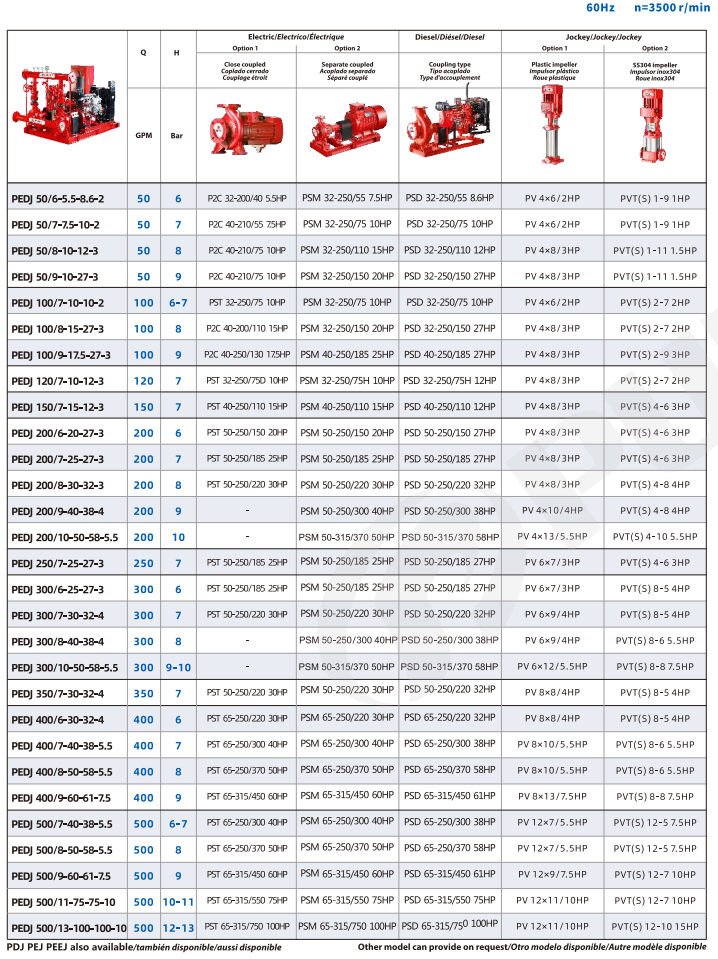

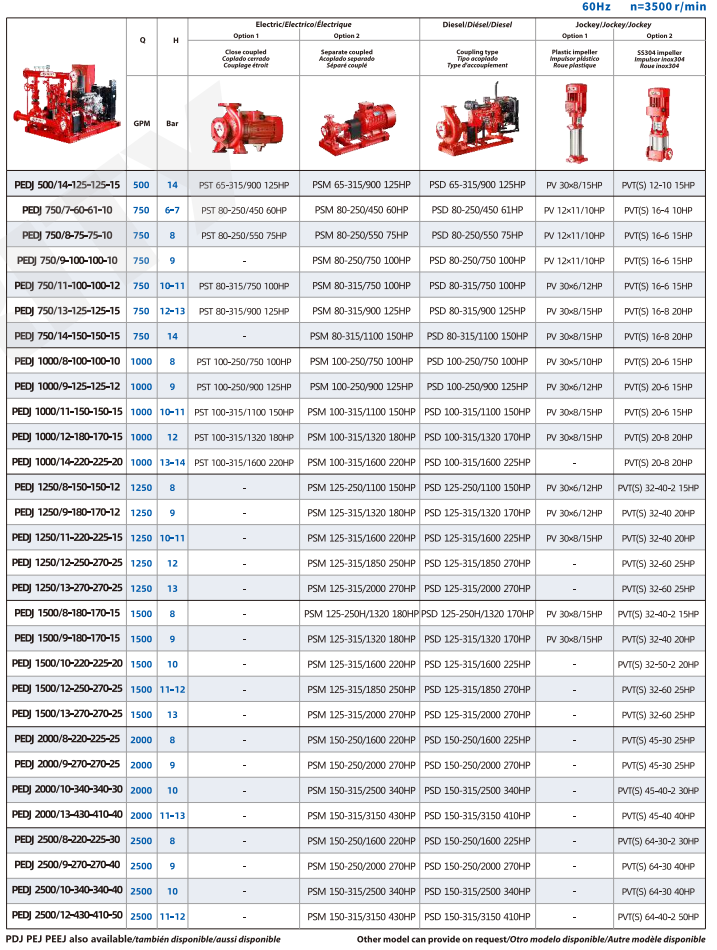

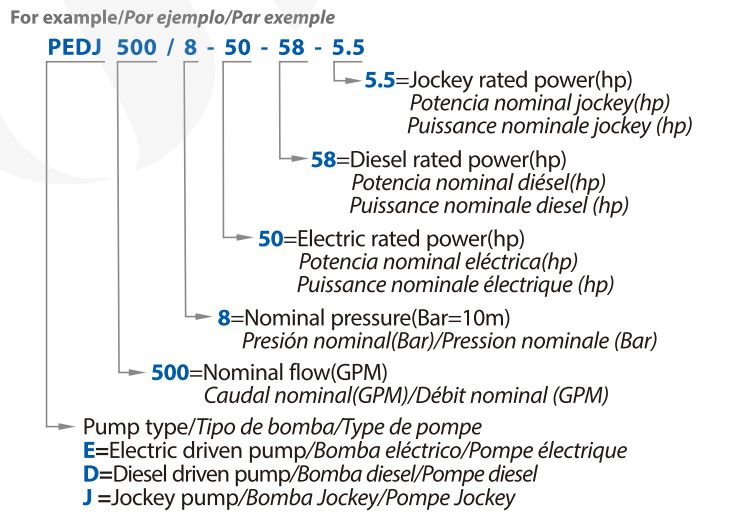

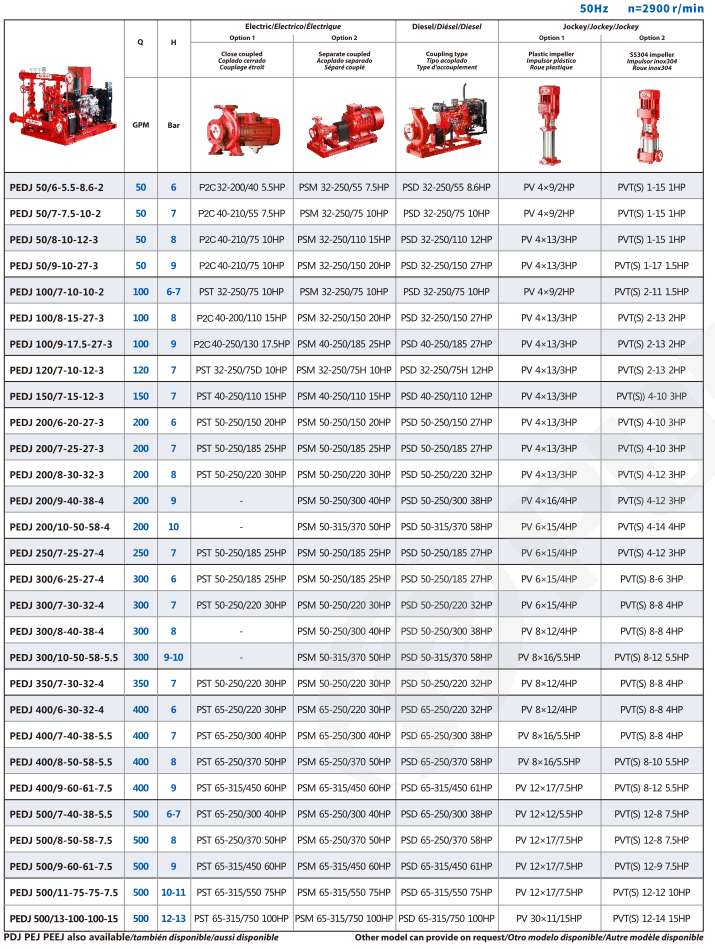

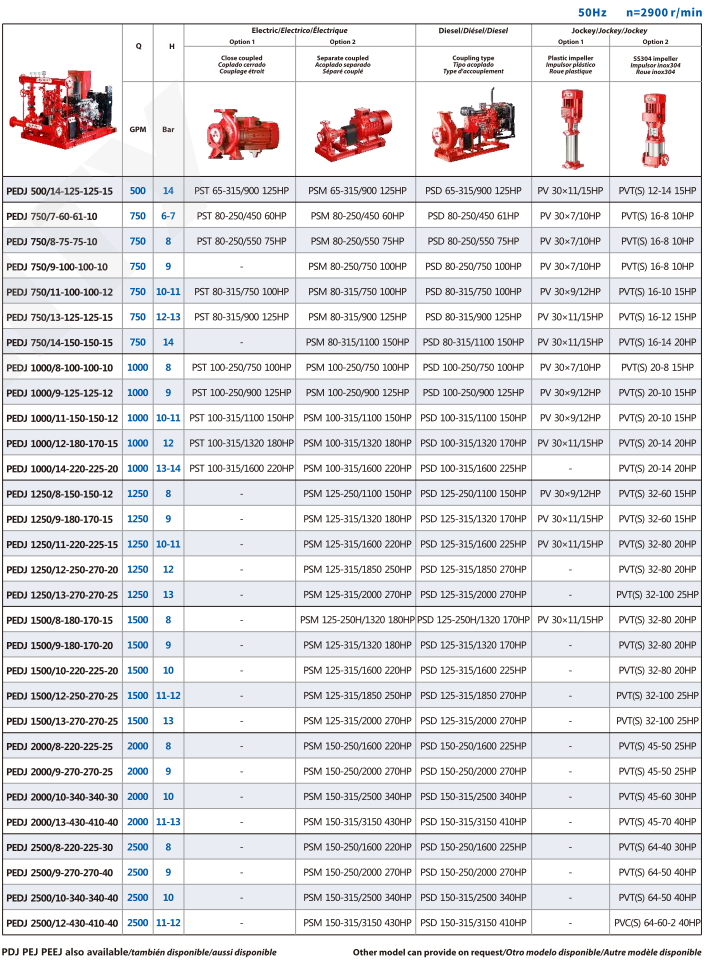

Diseñado con estructuras flexibles y múltiples configuraciones, el sistema de bombeo contra incendios Purity PEJ cumple con las especificaciones chinas y puede personalizarse para diversas aplicaciones en sistemas de extinción de incendios, incluyendo edificios comerciales, instalaciones industriales, complejos de gran altura y proyectos de suministro de agua de emergencia. Su adaptabilidad garantiza un rendimiento fiable en diferentes entornos de instalación.

Con 15 años de experiencia en la industria de bombas contra incendios, Purity se ha consolidado como uno de los principales fabricantes de bombas contra incendios en China, exportando sus productos a más de 130 países. Nuestra fábrica, con una superficie de 60.000 metros cuadrados, cuenta con el respaldo de un equipo profesional de I+D dedicado a la innovación, la seguridad y la fiabilidad a largo plazo. Como fabricantes de bombas contra incendios de emergencia con amplia experiencia, nos comprometemos a ofrecer una calidad reconocida internacionalmente.

Purity busca distribuidores y socios a nivel mundial. Si busca bombas para sistemas contra incendios duraderas y eficientes, o si desea adquirir una bomba contra incendios de alto rendimiento directamente de un fabricante chino de confianza, contáctenos hoy mismo. Esperamos convertirnos en su proveedor preferido de bombas contra incendios en todo el mundo.

El sistema de bomba contra incendios Purity PEJ está diseñado para clientes que buscan una solución de alta calidad y fácil de usar, proveniente de un fabricante de bombas contra incendios de confianza en China. Gracias a su diseño operativo simplificado, la unidad PEJ no requiere ensamblaje adicional, lo que permite una instalación y puesta en marcha rápidas, ideal para proyectos urgentes y situaciones de emergencia.

Para satisfacer las exigencias de eficiencia actuales, el sistema PEJ combina una bomba jockey de bajo consumo con una bomba contra incendios eléctrica de alta potencia, lo que proporciona un ahorro energético excepcional y mantiene una presión estable. Esta configuración inteligente reduce significativamente el consumo eléctrico, convirtiendo al PEJ en una excelente opción para promotores, constructores y distribuidores que buscan bombas contra incendios que ofrezcan rendimiento y una buena relación calidad-precio.

Diseñado con estructuras flexibles y múltiples configuraciones, el sistema de bombeo contra incendios Purity PEJ cumple con las especificaciones chinas y puede personalizarse para diversas aplicaciones en sistemas de extinción de incendios, incluyendo edificios comerciales, instalaciones industriales, complejos de gran altura y proyectos de suministro de agua de emergencia. Su adaptabilidad garantiza un rendimiento fiable en diferentes entornos de instalación.

Con 15 años de experiencia en la industria de bombas contra incendios, Purity se ha consolidado como uno de los principales fabricantes de bombas contra incendios en China, exportando sus productos a más de 130 países. Nuestra fábrica, con una superficie de 60.000 metros cuadrados, cuenta con el respaldo de un equipo profesional de I+D dedicado a la innovación, la seguridad y la fiabilidad a largo plazo. Como fabricantes de bombas contra incendios de emergencia con amplia experiencia, nos comprometemos a ofrecer una calidad reconocida internacionalmente.

Purity busca distribuidores y socios a nivel mundial. Si busca bombas para sistemas contra incendios duraderas y eficientes, o si desea adquirir una bomba contra incendios de alto rendimiento directamente de un fabricante chino de confianza, contáctenos hoy mismo. Esperamos convertirnos en su proveedor preferido de bombas contra incendios en todo el mundo.