Como fabricante líder de bombas centrífugas horizontales, Purity presenta nuestra bomba centrífuga de acoplamiento cerrado serie PST, diseñada para ofrecer un rendimiento excepcional en diversas aplicaciones industriales.

Características destacadas del producto:

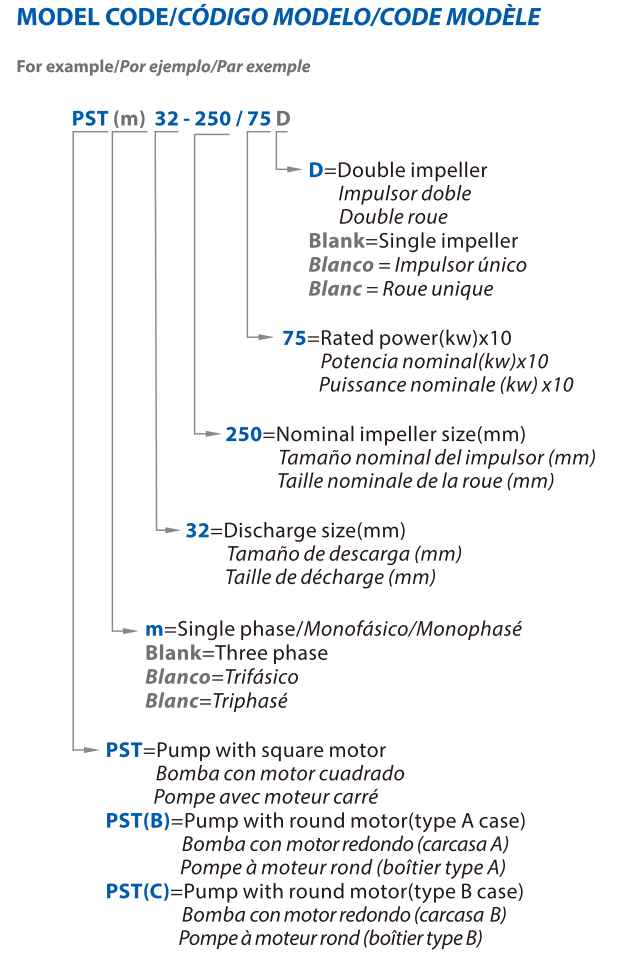

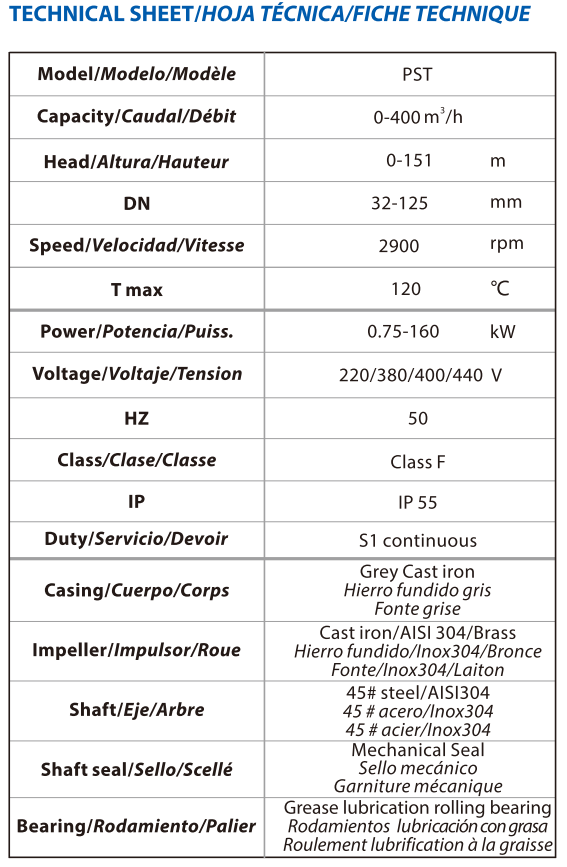

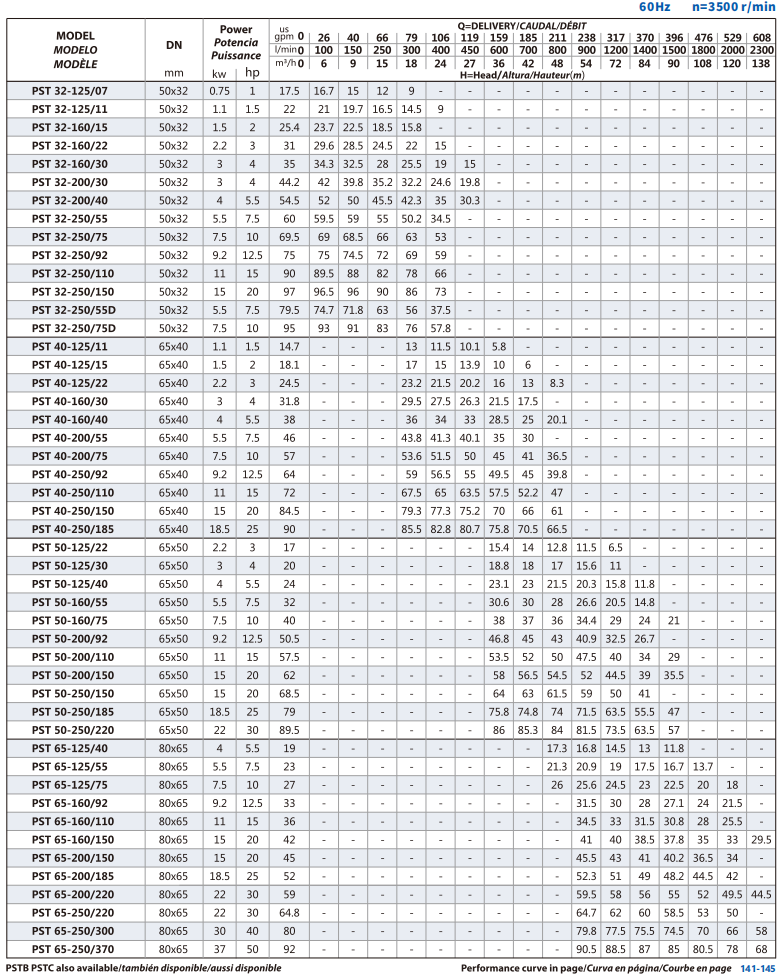

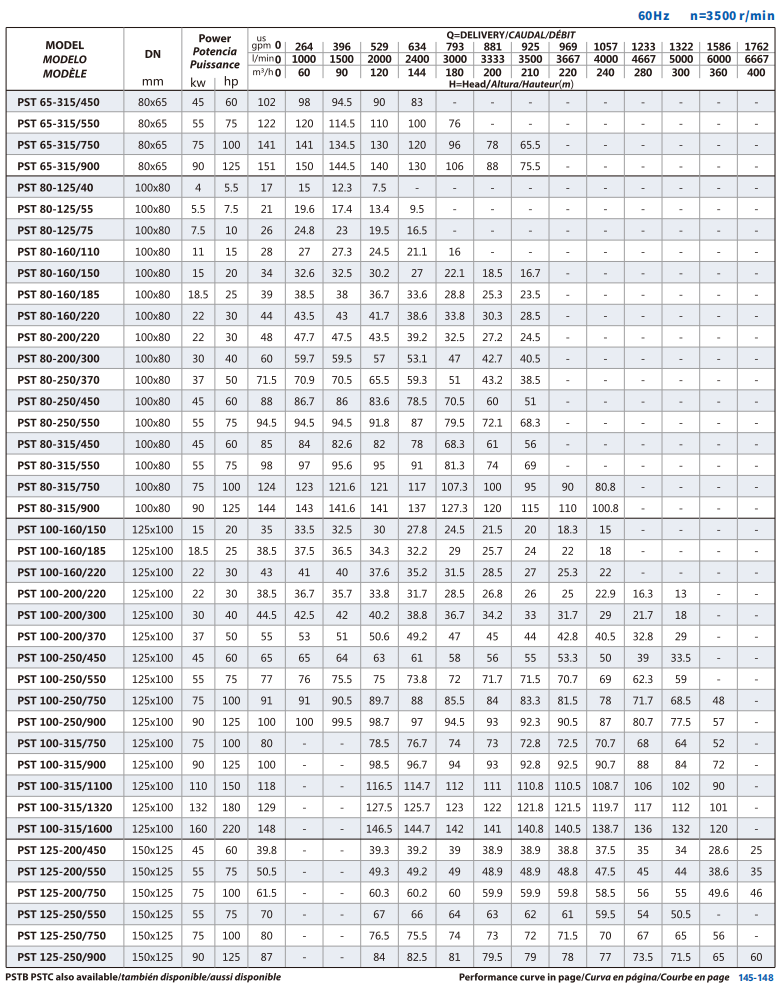

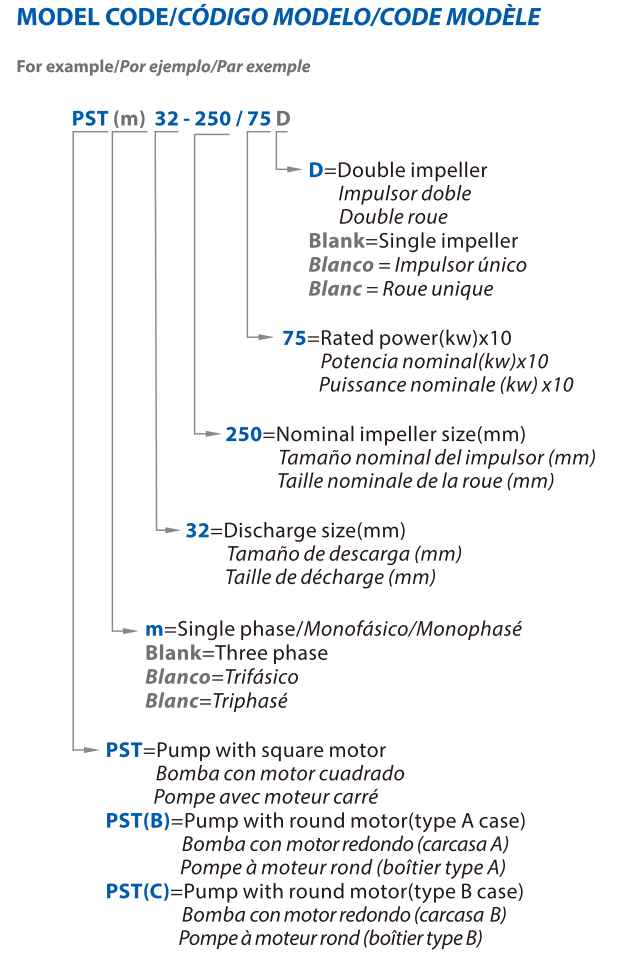

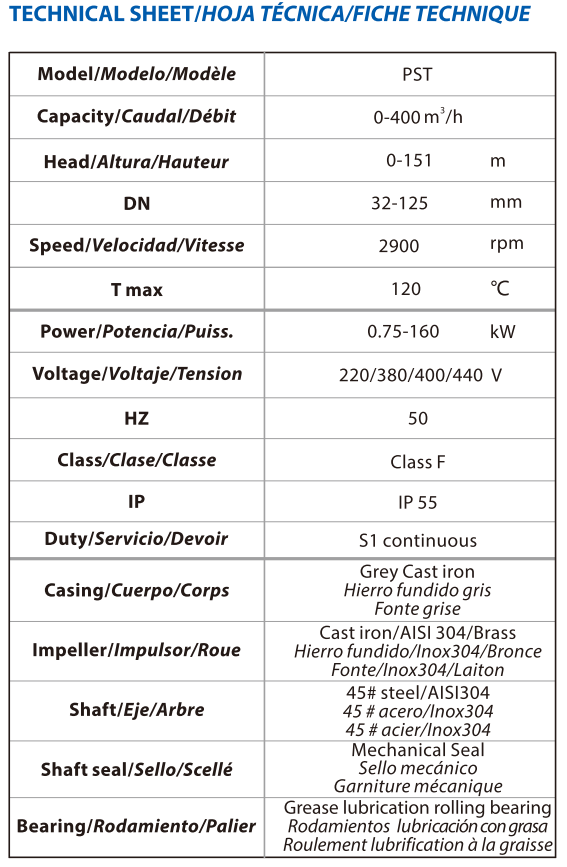

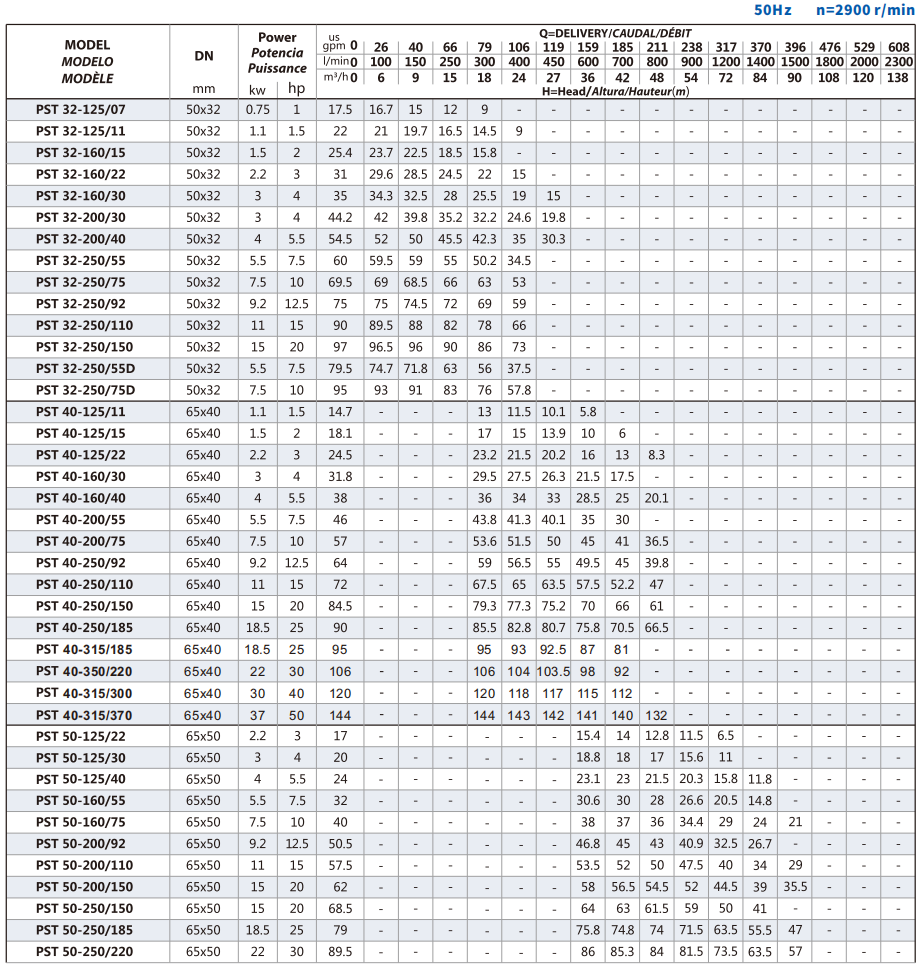

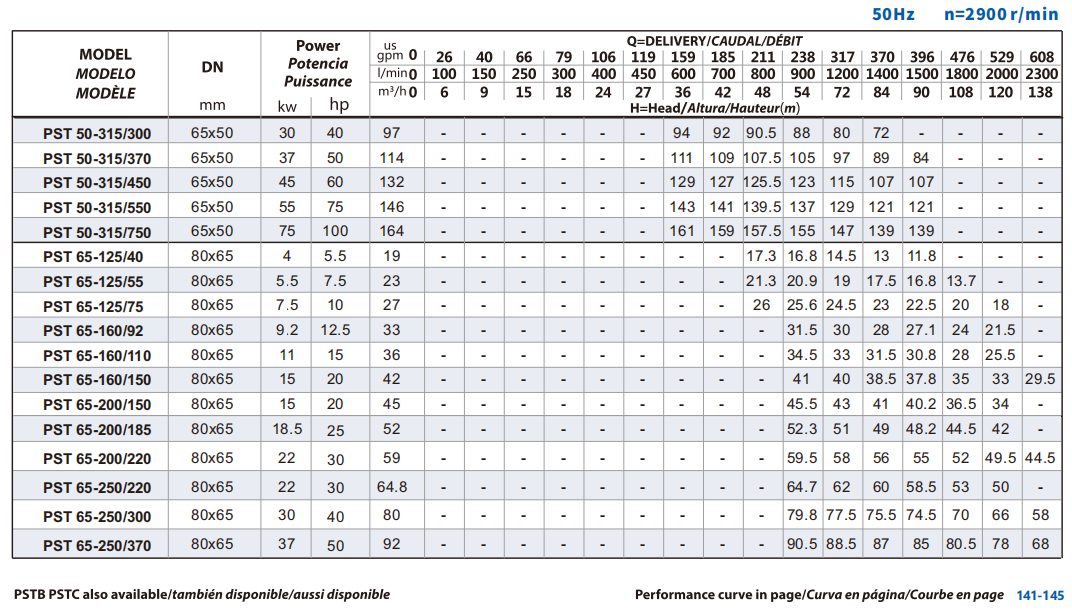

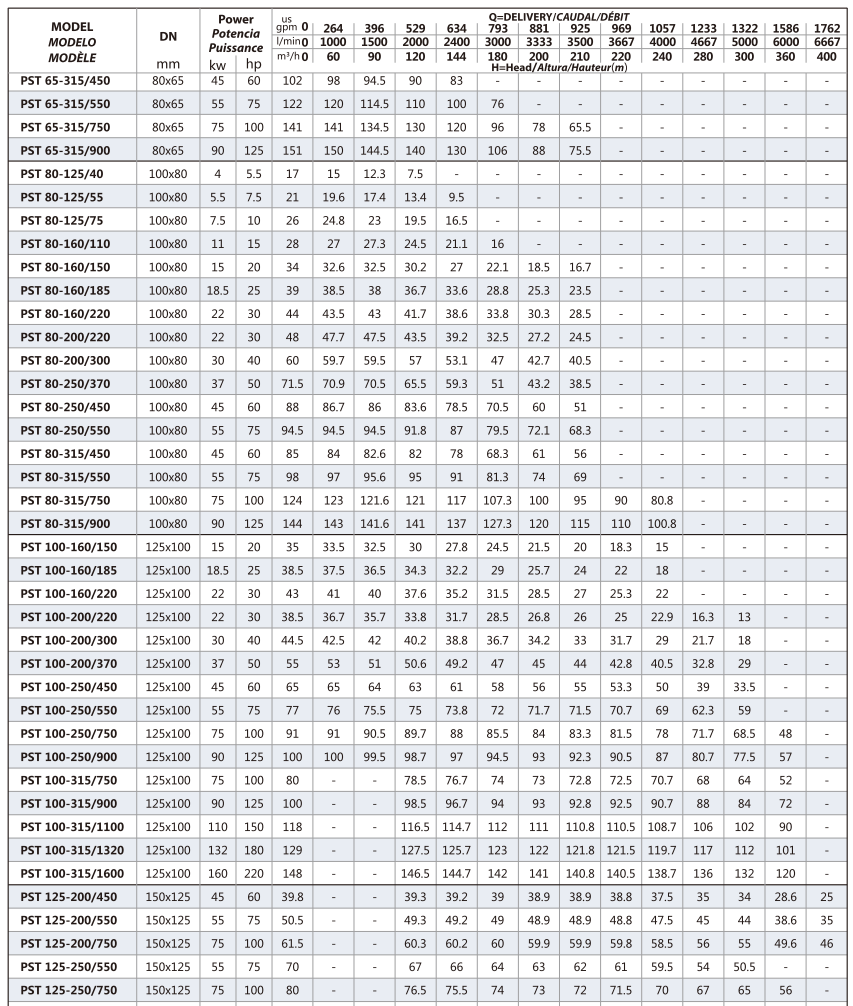

1.Especificaciones completas: Nuestras especificaciones de bombas centrífugas horizontales cubren una gama completa de modelos, tamaños (32-125 mm) y opciones de potencia (0,75-160 kW) para satisfacer diversas demandas operativas.

2.Opciones de impulsor premium: Impulsor de hierro fundido estándar con configuraciones opcionales de bronce/acero inoxidable para diferentes requisitos de manejo de fluidos

3.Construcción robusta: Cuenta con grado de protección IP55 y aislamiento clase F para un rendimiento confiable en entornos desafiantes

La bomba centrífuga de impulsor cerrado de la serie PST ofrece:

✓ Garantía de calidad con certificación CE

✓ Operación energéticamente eficiente

✓ Diseño de bajo mantenimiento

✓ Rendimiento sin vibraciones

Las aplicaciones ideales incluyen:

- Sistemas de suministro de agua

- Operaciones de HVAC

- Procesamiento industrial

- Proyectos de riego

Actualmente estamos ampliando nuestra red de distribución global y buscando socios calificados.

¿Por qué asociarse con Purity?

• Más de 15 años de experiencia en bombas centrífugas

• Soluciones personalizables para requisitos especiales

• Precios competitivos con soporte posventa confiable

¡Contáctenos hoy para conocer las especificaciones detalladas de las bombas centrífugas horizontales o las oportunidades de distribución!

Como fabricante líder de bombas centrífugas horizontales, Purity presenta nuestra bomba centrífuga de acoplamiento cerrado serie PST, diseñada para ofrecer un rendimiento excepcional en diversas aplicaciones industriales.

Características destacadas del producto:

1.Especificaciones completas: Nuestras especificaciones de bombas centrífugas horizontales cubren una gama completa de modelos, tamaños (32-125 mm) y opciones de potencia (0,75-160 kW) para satisfacer diversas demandas operativas.

2.Opciones de impulsor premium: Impulsor de hierro fundido estándar con configuraciones opcionales de bronce/acero inoxidable para diferentes requisitos de manejo de fluidos

3.Construcción robusta: Cuenta con grado de protección IP55 y aislamiento clase F para un rendimiento confiable en entornos desafiantes

La bomba centrífuga de impulsor cerrado de la serie PST ofrece:

✓ Garantía de calidad con certificación CE

✓ Operación energéticamente eficiente

✓ Diseño de bajo mantenimiento

✓ Rendimiento sin vibraciones

Las aplicaciones ideales incluyen:

- Sistemas de suministro de agua

- Operaciones de HVAC

- Procesamiento industrial

- Proyectos de riego

Actualmente estamos ampliando nuestra red de distribución global y buscando socios calificados.

¿Por qué asociarse con Purity?

• Más de 15 años de experiencia en bombas centrífugas

• Soluciones personalizables para requisitos especiales

• Precios competitivos con soporte posventa confiable

¡Contáctenos hoy para conocer las especificaciones detalladas de las bombas centrífugas horizontales o las oportunidades de distribución!