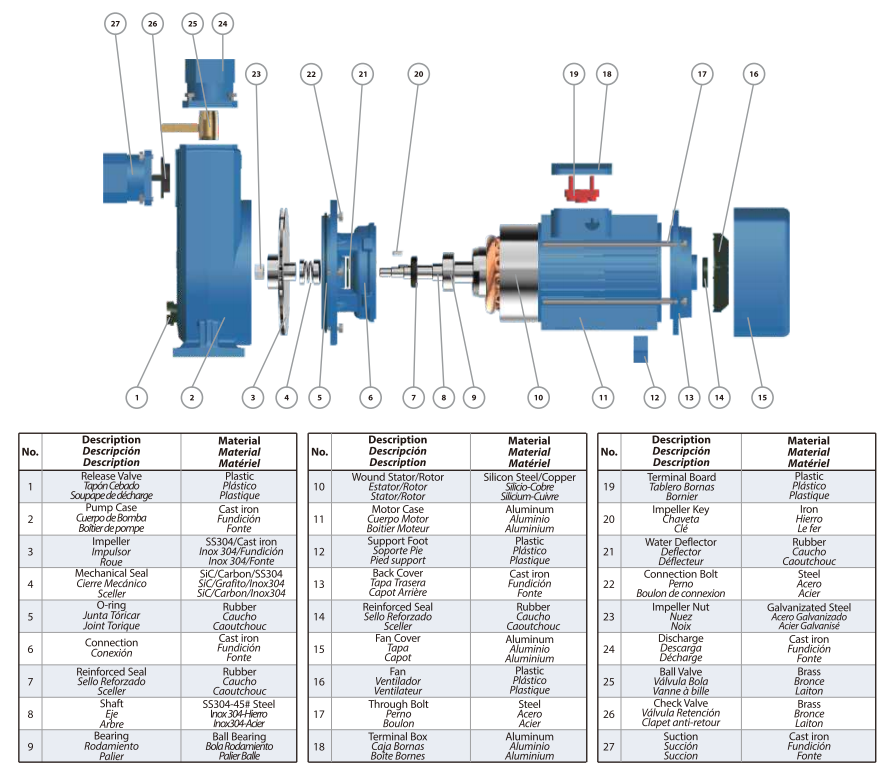

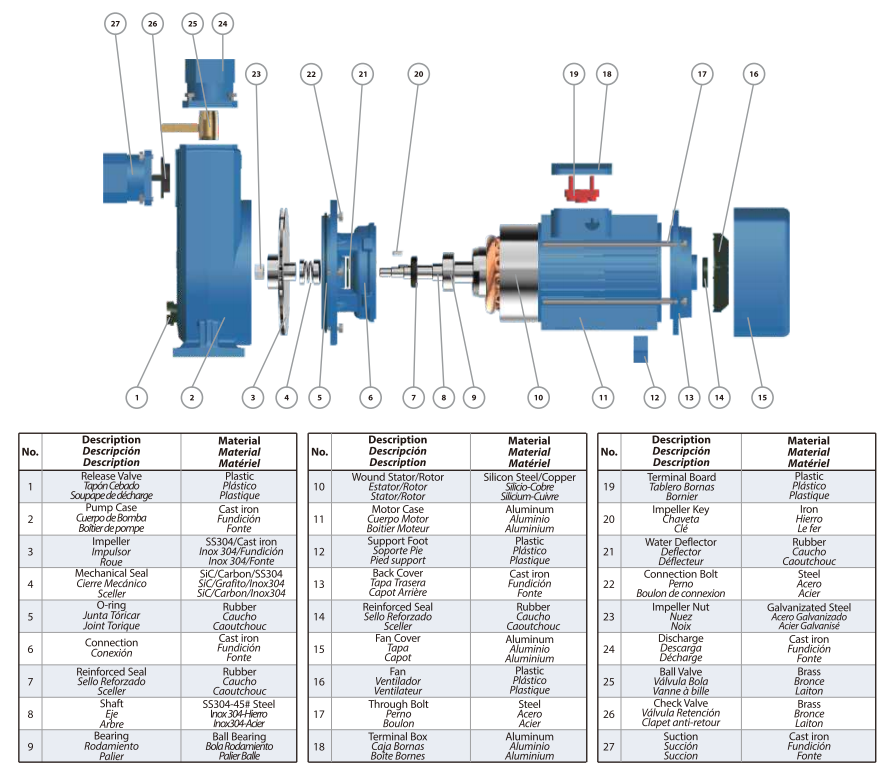

La bomba centrífuga autocebante Purity PXZ presenta un diseño moderno que realza el reconocimiento de la marca y ofrece un rendimiento excepcional en aplicaciones exigentes. Diseñada con innovación y durabilidad en mente, esta bomba es una solución confiable para industrias que requieren una transferencia de fluidos eficiente y duradera.

Una característica clave de la serie PXZ es el uso de un eje soldado de acero inoxidable 304, que mejora significativamente la resistencia a la oxidación y prolonga la vida útil de la bomba. Esto la convierte en la opción ideal entre las bombas centrífugas autocebantes para el manejo de diversos procesos industriales y de suministro de agua.

El modelo PZX está equipado con un motor de bajo consumo con certificación nacional. Con bobinados de cobre puro, baja elevación de temperatura y alta eficiencia, esta bomba centrífuga autocebante horizontal garantiza un funcionamiento constante y minimiza el consumo de energía. Su ingeniería avanzada permite a los usuarios lograr fiabilidad y rentabilidad, convirtiéndola en una de las opciones más confiables para las industrias a nivel mundial.

Como fabricante líder de bombas centrífugas horizontales autocebantes, Purity cuenta con más de 15 años de experiencia en la producción de bombas de alta calidad. Nuestros productos cuentan con las certificaciones CE, ISO y SASO, cumpliendo con los estrictos estándares internacionales de seguridad y rendimiento. Con presencia global en más de 130 países, nuestras bombas han sido probadas y comprobadas tanto por el tiempo como por la experiencia de nuestros clientes.

Purity se dedica a la innovación, la calidad de sus productos y la satisfacción del cliente. Buscamos activamente distribuidores y socios globales para expandir nuestra red internacional. Si busca un proveedor confiable de bombas centrífugas autocebantes horizontales, Purity es su mejor opción. Contáctenos hoy mismo para hablar sobre oportunidades de colaboración y descubrir el valor de trabajar con un fabricante profesional de bombas centrífugas.

La bomba centrífuga autocebante Purity PXZ presenta un diseño moderno que realza el reconocimiento de la marca y ofrece un rendimiento excepcional en aplicaciones exigentes. Diseñada con innovación y durabilidad en mente, esta bomba es una solución confiable para industrias que requieren una transferencia de fluidos eficiente y duradera.

Una característica clave de la serie PXZ es el uso de un eje soldado de acero inoxidable 304, que mejora significativamente la resistencia a la oxidación y prolonga la vida útil de la bomba. Esto la convierte en la opción ideal entre las bombas centrífugas autocebantes para el manejo de diversos procesos industriales y de suministro de agua.

El modelo PZX está equipado con un motor de bajo consumo con certificación nacional. Con bobinados de cobre puro, baja elevación de temperatura y alta eficiencia, esta bomba centrífuga autocebante horizontal garantiza un funcionamiento constante y minimiza el consumo de energía. Su ingeniería avanzada permite a los usuarios lograr fiabilidad y rentabilidad, convirtiéndola en una de las opciones más confiables para las industrias a nivel mundial.

Como fabricante líder de bombas centrífugas horizontales autocebantes, Purity cuenta con más de 15 años de experiencia en la producción de bombas de alta calidad. Nuestros productos cuentan con las certificaciones CE, ISO y SASO, cumpliendo con los estrictos estándares internacionales de seguridad y rendimiento. Con presencia global en más de 130 países, nuestras bombas han sido probadas y comprobadas tanto por el tiempo como por la experiencia de nuestros clientes.

Purity se dedica a la innovación, la calidad de sus productos y la satisfacción del cliente. Buscamos activamente distribuidores y socios globales para expandir nuestra red internacional. Si busca un proveedor confiable de bombas centrífugas autocebantes horizontales, Purity es su mejor opción. Contáctenos hoy mismo para hablar sobre oportunidades de colaboración y descubrir el valor de trabajar con un fabricante profesional de bombas centrífugas.