Introducción del producto

La bomba centrífuga de succión simple y etapa Purity PC está equipada con un motor YE3 de alta eficiencia y ahorro de energía con clasificación de protección IP55, que ofrece una excelente resistencia al polvo y la humedad. Esto garantiza un funcionamiento seguro y fiable incluso en entornos exigentes, a la vez que reduce eficazmente el consumo de energía.

En la industria de las bombas centrífugas, se utilizan rodamientos NSK de alta calidad y un sello mecánico resistente al desgaste para minimizar la fricción y las pérdidas mecánicas durante el funcionamiento. Estos componentes de primera calidad mejoran significativamente la durabilidad, reducen el ruido y prolongan la vida útil de la bomba centrífuga de succión simple y etapa.

La bomba centrífuga de succión simple y etapa Purity PC está diseñada para satisfacer diversos requisitos de caudal, ofreciendo soluciones flexibles para sistemas tanto pequeños como grandes. Los usuarios pueden elegir entre un impulsor de hierro fundido o latón, según el fluido de trabajo y el entorno de aplicación. Esta adaptabilidad la hace adecuada para el suministro de agua residencial, riego, circulación de sistemas HVAC y sistemas de agua industriales en general.

Con conexiones roscadas de entrada y salida, las bombas centrífugas de refuerzo Purity PC permiten una instalación rápida y sencilla, lo que reduce el tiempo de configuración y la complejidad del mantenimiento. Compacta, eficiente y duradera, la bomba centrífuga de succión simple Purity combina un diseño avanzado con materiales de calidad para garantizar un suministro de agua fiable y un rendimiento constante en diversas condiciones de funcionamiento.

Si le interesa la bomba centrífuga de succión simple Purity PC, ¡no dude en consultarnos!

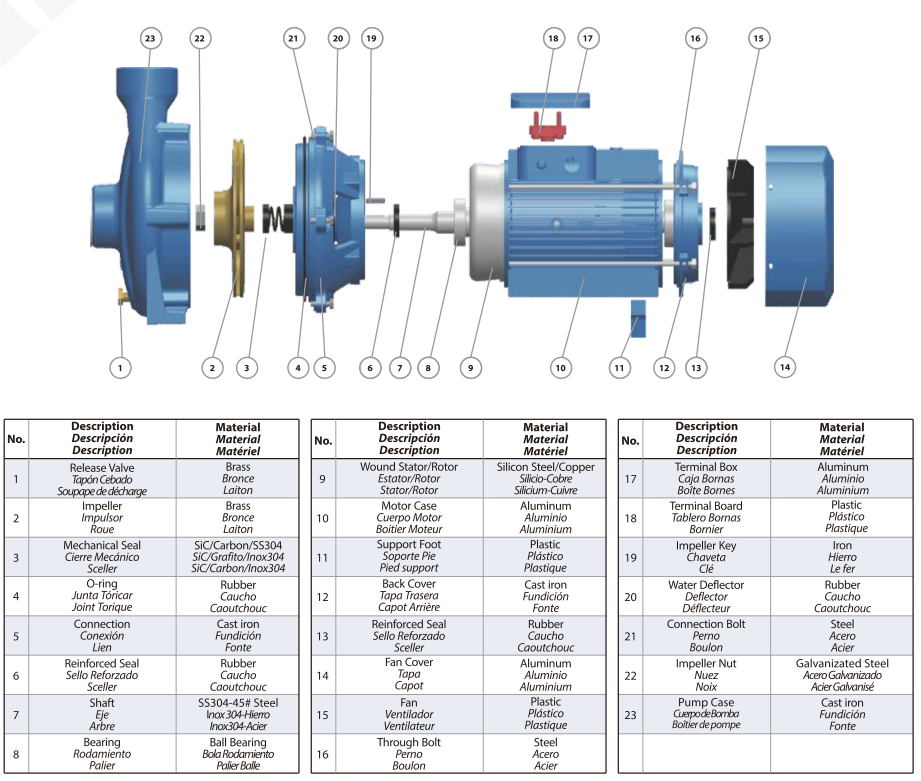

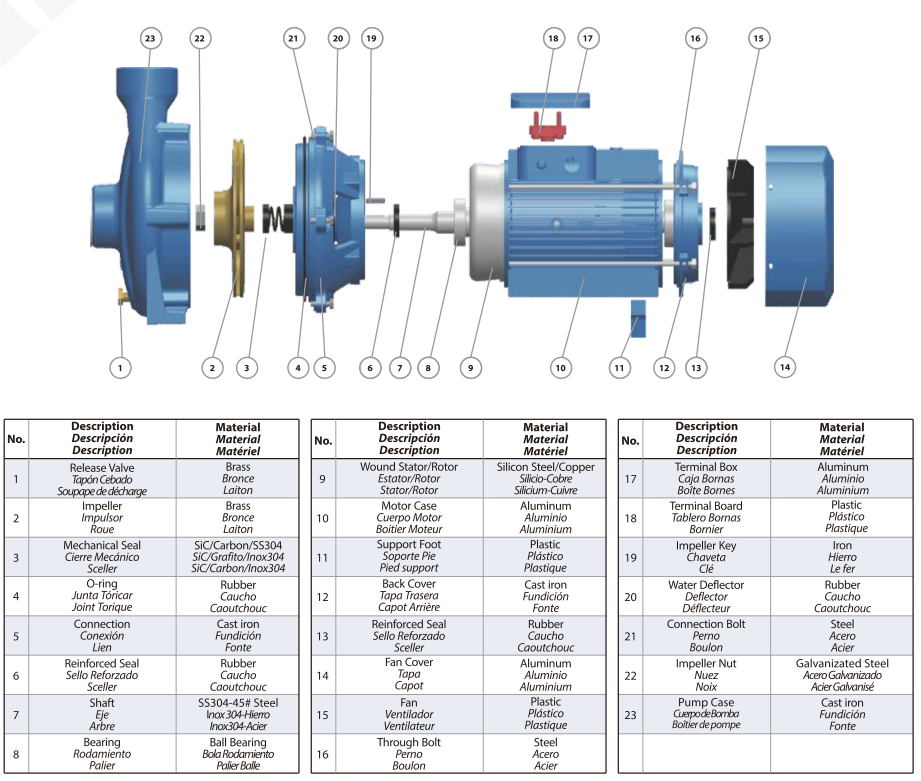

Componentes del producto

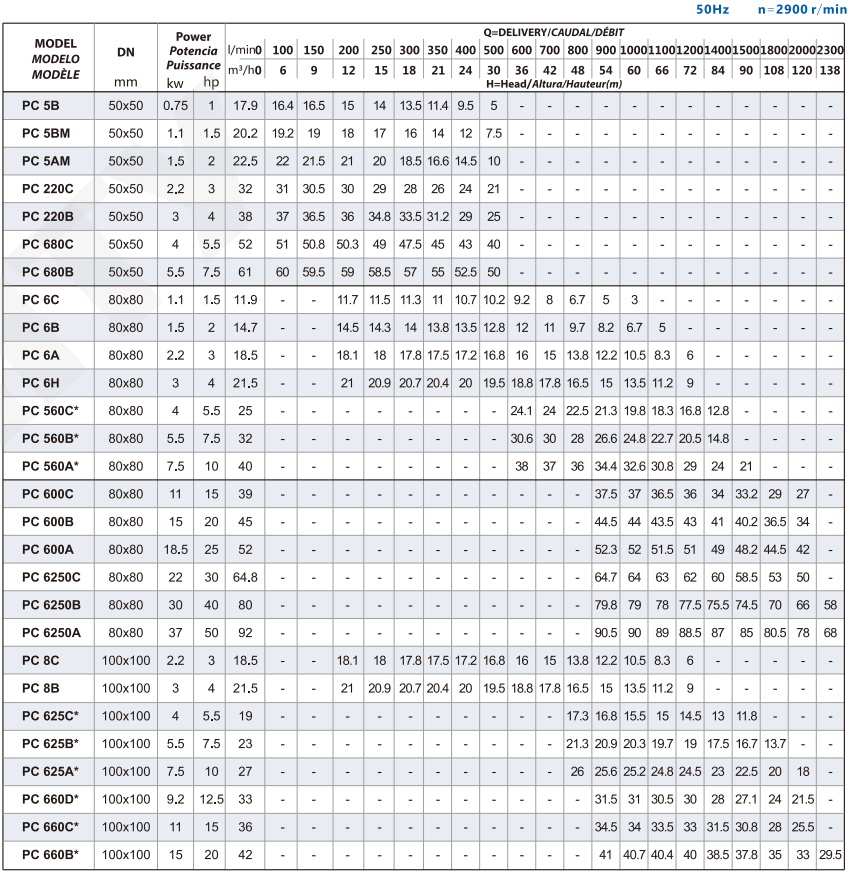

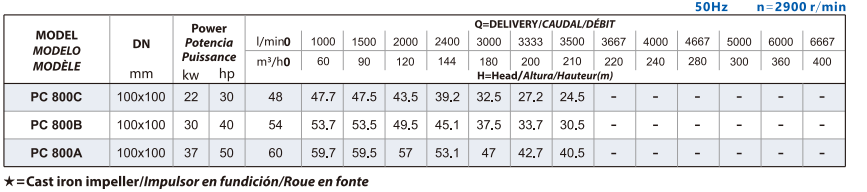

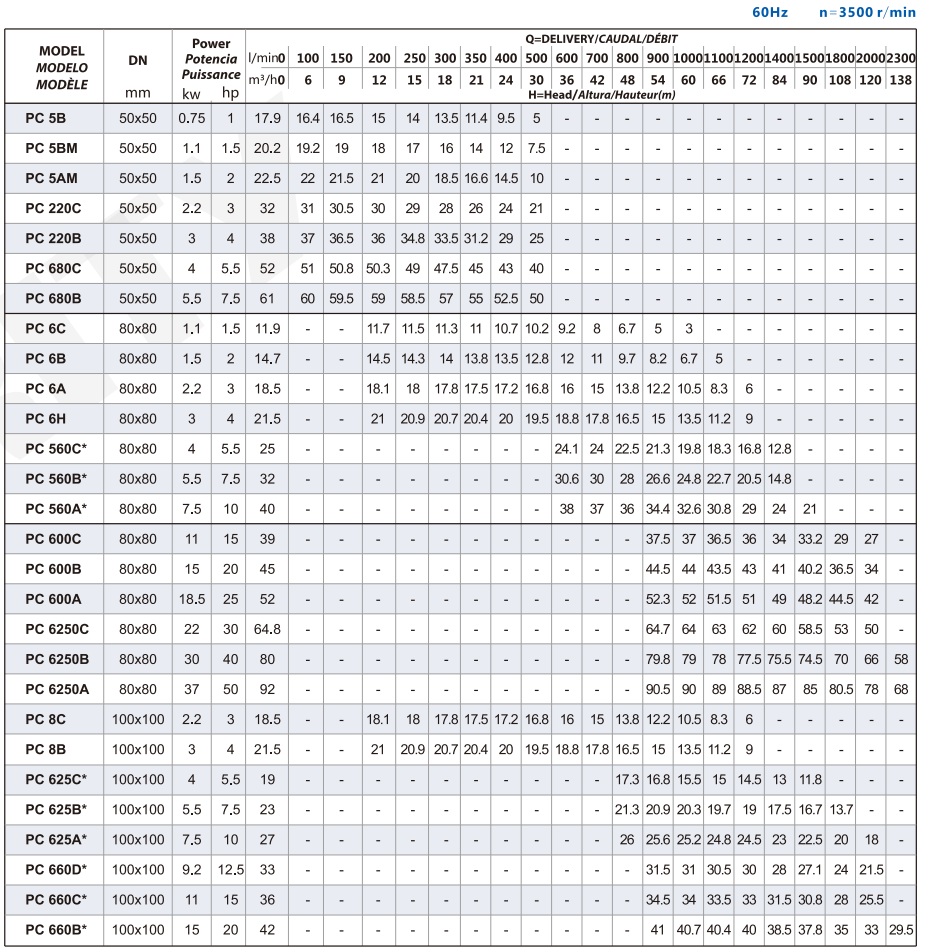

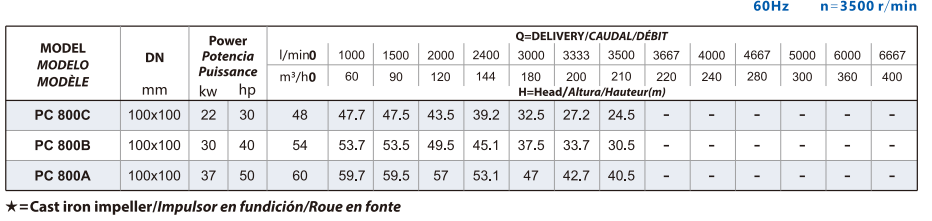

Parámetros del producto

Introducción del producto

La bomba centrífuga de succión simple y etapa Purity PC está equipada con un motor YE3 de alta eficiencia y ahorro de energía con clasificación de protección IP55, que ofrece una excelente resistencia al polvo y la humedad. Esto garantiza un funcionamiento seguro y fiable incluso en entornos exigentes, a la vez que reduce eficazmente el consumo de energía.

En la industria de las bombas centrífugas, se utilizan rodamientos NSK de alta calidad y un sello mecánico resistente al desgaste para minimizar la fricción y las pérdidas mecánicas durante el funcionamiento. Estos componentes de primera calidad mejoran significativamente la durabilidad, reducen el ruido y prolongan la vida útil de la bomba centrífuga de succión simple y etapa.

La bomba centrífuga de succión simple y etapa Purity PC está diseñada para satisfacer diversos requisitos de caudal, ofreciendo soluciones flexibles para sistemas tanto pequeños como grandes. Los usuarios pueden elegir entre un impulsor de hierro fundido o latón, según el fluido de trabajo y el entorno de aplicación. Esta adaptabilidad la hace adecuada para el suministro de agua residencial, riego, circulación de sistemas HVAC y sistemas de agua industriales en general.

Con conexiones roscadas de entrada y salida, las bombas centrífugas de refuerzo Purity PC permiten una instalación rápida y sencilla, lo que reduce el tiempo de configuración y la complejidad del mantenimiento. Compacta, eficiente y duradera, la bomba centrífuga de succión simple Purity combina un diseño avanzado con materiales de calidad para garantizar un suministro de agua fiable y un rendimiento constante en diversas condiciones de funcionamiento.

Si le interesa la bomba centrífuga de succión simple Purity PC, ¡no dude en consultarnos!

Componentes del producto

Parámetros del producto