Product Description

PEDT(P2C+PSD+Pressure Tank+Control Cabinet)

P2C

TECHNICAL DESCRIPTION

New double impeller centrifugal pump

Original design by PURITY

Both square motor & round motor available

YE3 high efficient motor, with protection IP55 class F

Pump case with anti-corrosive coating

Double impeller in brass

Shaft in stainless steel AISI 304 or galvanized iron

Suction and discharge port in G20 thread

Quality NSK bearing, wear resistance mechanical seal

APPLICATIONS

Suitable for use with clean water and liquids that are not chemically

aggressive towards the materials from which the pump is made.

The high efficiency and adaptability of these pumps to even the most

unusual of applications, makes them ideal for use in the domestic,

civil and industrial sectors; in particular for the distribution of water in

combination with pressure sets, for pressure boosting and in fire-fighting sets.

USING LIMITS

Liquid temperature between -10℃ and +120℃

Ambient temperature up to +50℃

Max. working pressure 16 bar

Continuous service S1

PD

TECHNICAL DATA

|

Model |

178 |

186 |

188 |

192 |

380 |

385 |

480 |

485 |

490N |

490 |

495 |

|

Type |

Single-cylinder,4-stroke,air-cooled |

Direct Injection, Water-cooling, Four Stroke |

|||||||||

|

Intake Type |

Naturally Aspirated |

||||||||||

|

Bore*Stroke(mm*mm) |

78*62 |

86*72 |

88*75 |

92*75 |

80*90 |

85*90 |

80*90 |

85*100 |

90*100 |

90*105 |

95*105 |

|

Cylinder No. |

1 |

1 |

1 |

1 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

|

Displacement (L) |

0.296 |

0.418 |

0.456 |

0.499 |

1.357 |

1.532 |

1.8 |

2.27 |

2.54 |

2.67 |

2.977 |

|

Rated Power/ Speed(kW/r/min) |

3.7/3000 4.0/3600 |

5.7/3000 6.3/3600 |

6.6/3000 7.2/3600 |

7.5/3000 8.2/3600 |

20/3000 |

24/3000 |

28/3000 |

26/3000 |

42/3000 |

45/3000 |

50/3000 |

|

Horse Power |

5.0/3000 5.5/3600 |

7.8/3000 8.6/3600 |

9.0/3000 10.0/3600 |

10.2/3000 12.0/3600 |

27 |

32 |

38 |

49 |

58 |

61 |

68 |

|

Power Coverage(kW) |

≤11 |

≤11 |

≤11 |

≤11 |

≤37 |

≤37 |

≤37 |

≤55 |

≤55 |

≤55 |

≤75 |

|

Model |

498 |

4102 |

4105 |

4108 |

485Z |

490NZ |

490Z |

498Z |

4102Z |

4105Z |

4108Z |

|

Type |

Direct Injection, Water-cooling, Four Stroke |

||||||||||

|

Intake Type |

Naturally Aspirated |

Turbo-charging |

|||||||||

|

Bore*Stroke(mm*mm) |

98*105 |

102*118 |

105*118 |

108*118 |

85*100 |

90*100 |

90*105 |

98*105 |

102*118 |

105*118 |

108*118 |

|

Cylinder No. |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

Displacement (L) |

3.168 |

3.857 |

4.087 |

4.324 |

2.27 |

2.54 |

2.67 |

3.168 |

3.857 |

4.087 |

4.324 |

|

Rated Power/ Speed(kW/r/min) |

54/3000 |

62/3000 |

67/3000 |

73/3000 |

44/3000 |

50/3000 |

55/3000 |

60/3000 |

73/3000 |

75/3000 |

83/3000 |

|

Horse Power |

73 |

85 |

91 |

99 |

60 |

68 |

75 |

81 |

99 |

102 |

113 |

|

Power Coverage(kW) |

≤75 |

≤100 |

≤100 |

≤100 |

≤55 |

≤55 |

≤55 |

≤75 |

≤100 |

≤100 |

≤100 |

P2C

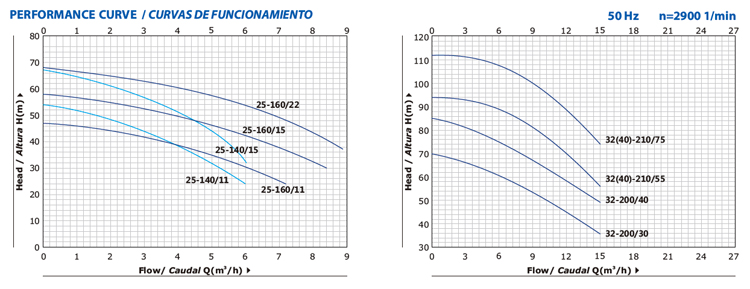

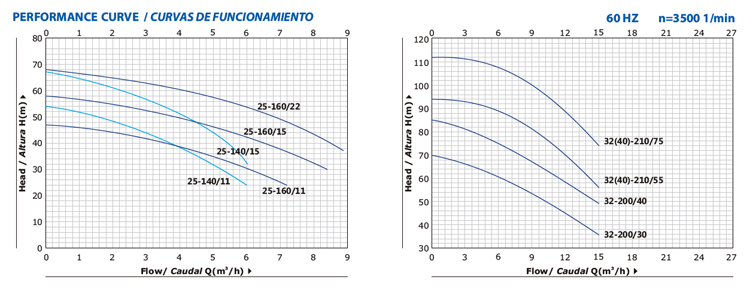

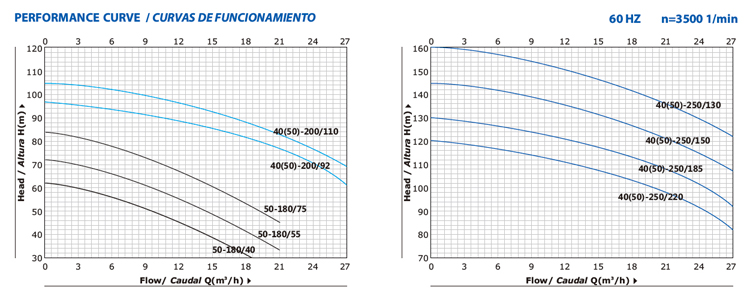

TECHNICAL DATA / DATOS TÉCNICOS 50Hz n=2900 1/min

|

MODEL |

Power |

l/min |

Q=DELIVERY |

DN |

|||||||||||||||||||

|

0 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

140 |

160 |

180 |

200 |

250 |

300 |

350 |

400 |

450 |

|||||

|

kw |

hp |

m³/h |

0 |

2.4 |

3 |

3.6 |

4.2 |

4.8 |

5.4 |

6 |

6.6 |

7.2 |

8.4 |

9.6 |

10.8 |

12 |

15 |

18 |

21 |

24 |

27 |

mm |

|

|

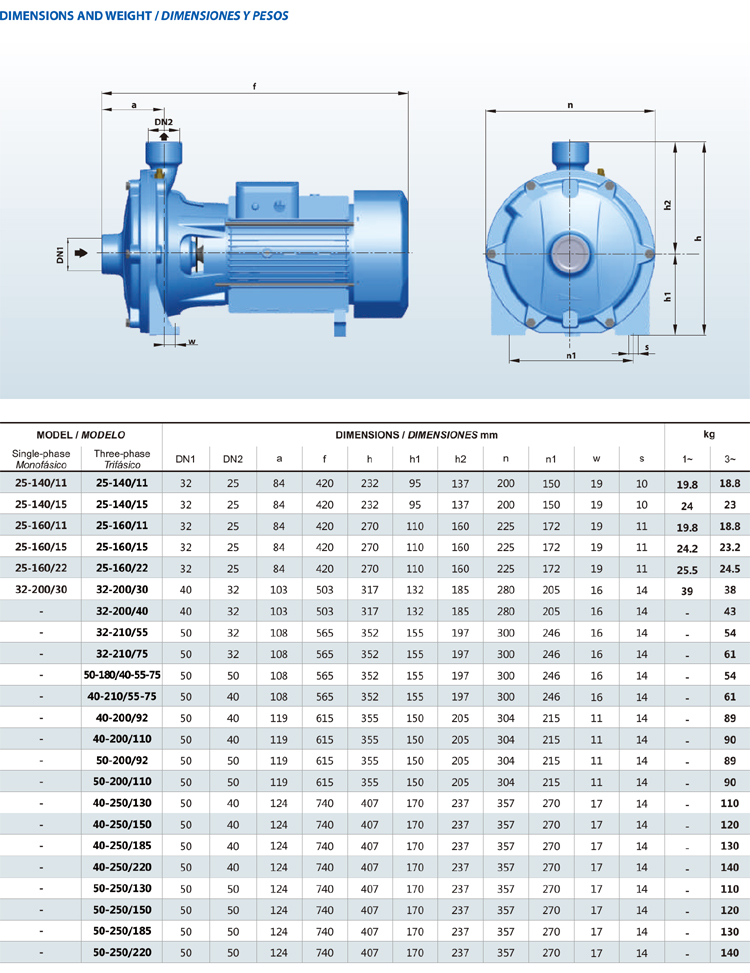

25-140/11 |

1.1 |

1.5 |

Head H(m) |

54 |

47.5 |

44.5 |

41 |

37 |

33 |

28 |

22 |

|

|

|

|

|

|

|

|

|

|

|

32x25 |

|

25-140/15 |

1.5 |

2 |

67 |

60 |

57 |

54 |

50 |

45 |

40 |

32 |

|

|

|

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/11 |

1.1 |

1.5 |

47 |

44 |

42 |

40 |

38 |

35 |

33 |

30 |

27 |

24 |

|

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/15 |

1.5 |

2 |

58 |

54 |

53 |

51 |

49 |

47 |

45 |

43 |

40 |

37 |

30 |

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/22 |

2.2 |

3 |

68 |

64.5 |

63 |

62 |

60 |

58 |

56 |

54 |

51 |

48 |

41 |

32 |

|

|

|

|

|

|

|

32x25 |

|

|

32-200/30 |

3 |

4 |

70 |

|

|

|

|

63 |

62 |

60.5 |

59 |

57 |

55 |

52 |

49.5 |

46.5 |

36 |

|

|

|

|

40x32 |

|

|

32-200/40 |

4 |

5.5 |

85 |

|

|

|

|

77 |

76 |

75 |

74 |

72 |

69 |

66 |

62 |

58 |

49 |

|

|

|

|

40x32 |

|

|

32-210/55 |

5.5 |

7.5 |

94 |

|

|

|

|

91 |

90 |

89 |

87 |

85 |

83 |

79 |

75 |

70 |

56 |

|

|

|

|

50x32 |

|

|

32-210/75 |

7.5 |

10 |

112 |

|

|

|

|

110 |

109 |

108 |

107 |

105 |

102 |

99 |

94 |

89 |

74 |

|

|

|

|

50x32 |

|

|

40-210/55 |

5.5 |

7.5 |

94 |

|

|

|

|

91 |

90 |

89 |

87 |

85 |

83 |

79 |

75 |

70 |

56 |

|

|

|

|

50x40 |

|

|

40-210/75 |

7.5 |

10 |

112 |

|

|

|

|

110 |

109 |

108 |

107 |

105 |

102 |

99 |

94 |

89 |

74 |

|

|

|

|

50x40 |

|

|

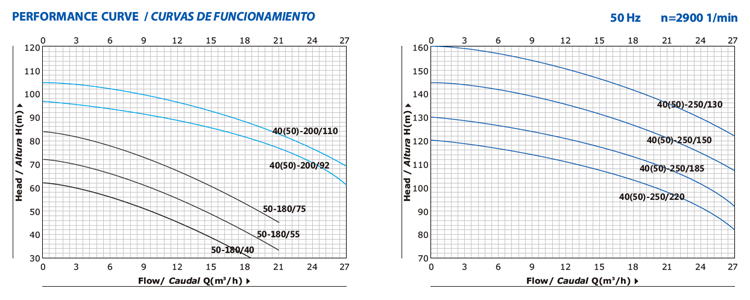

50-180/40 |

4 |

5.5 |

62 |

|

|

|

|

59 |

58 |

57 |

56 |

55 |

55 |

50 |

48 |

44 |

36 |

31 |

23 |

|

|

50x50 |

|

|

50-180/55 |

5.5 |

7.5 |

72 |

|

|

|

|

69 |

68 |

67 |

66 |

65 |

65 |

60 |

58 |

54 |

46 |

41 |

33 |

|

|

50x50 |

|

|

50-180/75 |

7.5 |

10 |

84 |

|

|

|

|

81 |

80 |

79 |

78 |

76 |

75 |

72 |

72 |

66 |

58 |

53 |

45 |

|

|

50x50 |

|

|

40-200/92 |

9.2 |

12.5 |

97 |

|

|

|

|

|

|

|

|

|

91.5 |

91 |

90 |

88 |

85 |

80 |

74 |

68 |

61 |

50x40 |

|

|

40-200/110 |

11 |

15 |

105 |

|

|

|

|

|

|

|

|

|

100 |

99 |

98 |

97 |

93 |

88 |

83 |

76 |

69 |

50x40 |

|

|

50-200/92 |

9.2 |

12.5 |

97 |

|

|

|

|

|

|

|

|

|

91.5 |

91 |

90 |

88 |

85 |

80 |

74 |

68 |

61 |

50x50 |

|

|

50-200/110 |

11 |

15 |

105 |

|

|

|

|

|

|

|

|

|

100 |

99 |

98 |

97 |

93 |

88 |

83 |

76 |

69 |

50x50 |

|

|

40-250/130 |

13 |

17.5 |

120 |

|

|

|

|

|

|

|

|

|

114 |

113 |

112 |

110 |

107 |

103 |

98 |

91 |

82 |

50x40 |

|

|

40-250/150 |

15 |

20 |

130 |

|

|

|

|

|

|

|

|

|

124 |

123 |

122 |

120 |

117 |

113 |

108 |

102 |

92 |

50x40 |

|

|

40-250/185 |

18.5 |

25 |

145 |

|

|

|

|

|

|

|

|

|

139 |

138 |

137 |

136 |

131 |

126 |

121 |

114 |

107 |

50x40 |

|

|

40-250/220 |

22 |

30 |

160 |

|

|

|

|

|

|

|

|

|

155 |

153 |

152 |

151 |

146 |

141 |

135 |

130 |

122 |

50x40 |

|

|

50-250/130 |

13 |

17.5 |

120 |

|

|

|

|

|

|

|

|

|

114 |

113 |

112 |

110 |

107 |

103 |

98 |

91 |

82 |

50x50 |

|

|

50-250/150 |

15 |

20 |

130 |

|

|

|

|

|

|

|

|

|

124 |

123 |

122 |

120 |

117 |

113 |

108 |

102 |

92 |

50x50 |

|

|

50-250/185 |

18.5 |

25 |

145 |

|

|

|

|

|

|

|

|

|

139 |

138 |

137 |

136 |

131 |

126 |

121 |

114 |

107 |

50x50 |

|

|

50-250/220 |

22 |

30 |

160 |

|

|

|

|

|

|

|

|

|

155 |

153 |

152 |

151 |

146 |

141 |

135 |

130 |

122 |

50x50 |

|

|

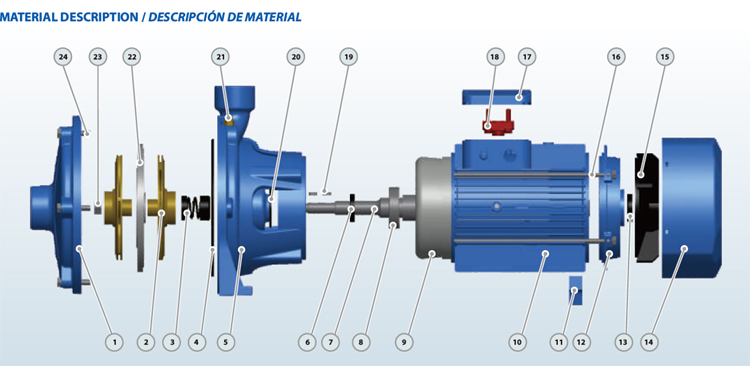

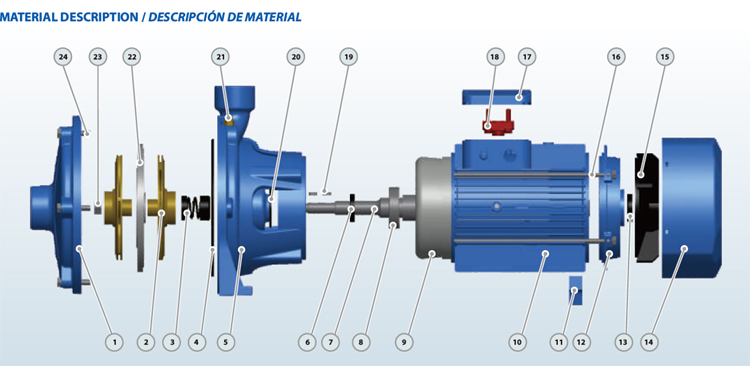

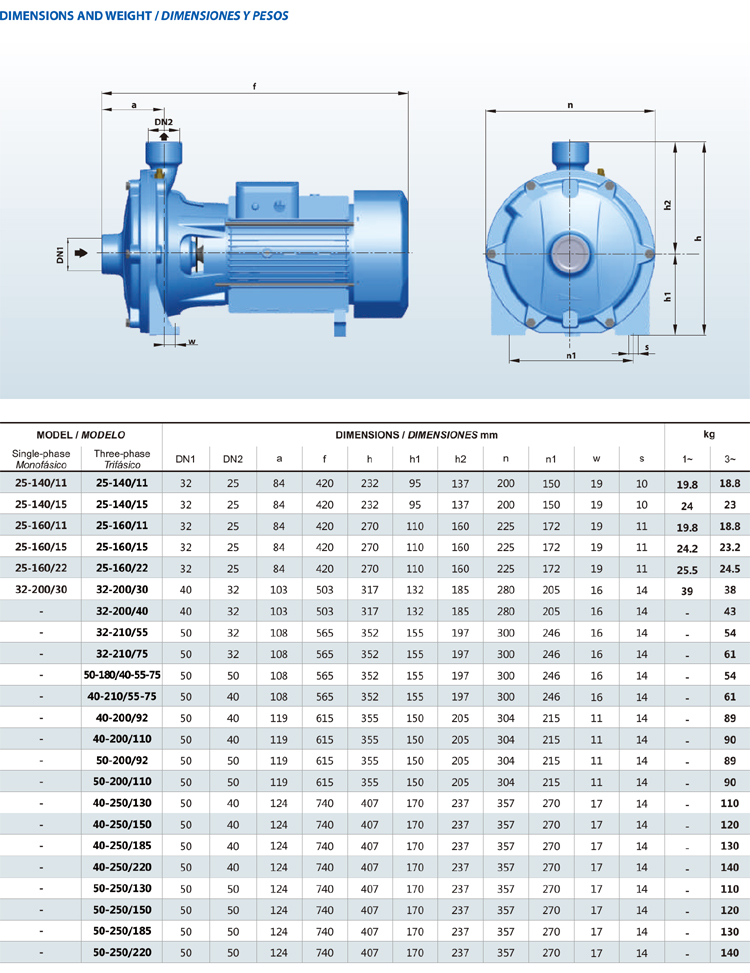

No. |

Description |

Material |

No. |

Description |

Material |

No. |

Description |

Material |

|

1 |

Pump Case |

Cast iron |

9 |

Wound Stator/Rotor |

Silicon Steel/Copper |

17 |

Terminal Box |

Aluminum |

|

2 |

Impeller |

Brass |

10 |

Motor Case |

Aluminum |

18 |

Terminal Board |

Plastic |

|

3 |

Mechanical Seal |

SiC/Carbon/SS304 |

11 |

Support Foot |

Plastic |

19 |

Impeller Key |

Iron |

|

4 |

O-ring |

Rubber |

12 |

Back Cover |

Cast iron |

20 |

Water Deflector |

Rubber |

|

5 |

Connection |

Cast iron |

13 |

Reinforced Seal |

Rubber |

21 |

Release Valve |

Brass |

|

6 |

Reinforced Seal |

Rubber |

14 |

Fan Cover |

Aluminum |

22 |

Diffuser |

Cast iron |

|

7 |

Shaft |

SS304/45# Steel |

15 |

Fan |

Plastic |

23 |

Impeller Nut |

Galvanizated Steel |

|

8 |

Bearing |

Ball Bearing |

16 |

Through Bolt |

Steel |

24 |

Connection Bolt |

Steel |

Spare Parts

Packaging & Shipping

Our Exhibition

Certifications

Product Description

PEDT(P2C+PSD+Pressure Tank+Control Cabinet)

P2C

TECHNICAL DESCRIPTION

New double impeller centrifugal pump

Original design by PURITY

Both square motor & round motor available

YE3 high efficient motor, with protection IP55 class F

Pump case with anti-corrosive coating

Double impeller in brass

Shaft in stainless steel AISI 304 or galvanized iron

Suction and discharge port in G20 thread

Quality NSK bearing, wear resistance mechanical seal

APPLICATIONS

Suitable for use with clean water and liquids that are not chemically

aggressive towards the materials from which the pump is made.

The high efficiency and adaptability of these pumps to even the most

unusual of applications, makes them ideal for use in the domestic,

civil and industrial sectors; in particular for the distribution of water in

combination with pressure sets, for pressure boosting and in fire-fighting sets.

USING LIMITS

Liquid temperature between -10℃ and +120℃

Ambient temperature up to +50℃

Max. working pressure 16 bar

Continuous service S1

PD

TECHNICAL DATA

|

Model |

178 |

186 |

188 |

192 |

380 |

385 |

480 |

485 |

490N |

490 |

495 |

|

Type |

Single-cylinder,4-stroke,air-cooled |

Direct Injection, Water-cooling, Four Stroke |

|||||||||

|

Intake Type |

Naturally Aspirated |

||||||||||

|

Bore*Stroke(mm*mm) |

78*62 |

86*72 |

88*75 |

92*75 |

80*90 |

85*90 |

80*90 |

85*100 |

90*100 |

90*105 |

95*105 |

|

Cylinder No. |

1 |

1 |

1 |

1 |

3 |

3 |

4 |

4 |

4 |

4 |

4 |

|

Displacement (L) |

0.296 |

0.418 |

0.456 |

0.499 |

1.357 |

1.532 |

1.8 |

2.27 |

2.54 |

2.67 |

2.977 |

|

Rated Power/ Speed(kW/r/min) |

3.7/3000 4.0/3600 |

5.7/3000 6.3/3600 |

6.6/3000 7.2/3600 |

7.5/3000 8.2/3600 |

20/3000 |

24/3000 |

28/3000 |

26/3000 |

42/3000 |

45/3000 |

50/3000 |

|

Horse Power |

5.0/3000 5.5/3600 |

7.8/3000 8.6/3600 |

9.0/3000 10.0/3600 |

10.2/3000 12.0/3600 |

27 |

32 |

38 |

49 |

58 |

61 |

68 |

|

Power Coverage(kW) |

≤11 |

≤11 |

≤11 |

≤11 |

≤37 |

≤37 |

≤37 |

≤55 |

≤55 |

≤55 |

≤75 |

|

Model |

498 |

4102 |

4105 |

4108 |

485Z |

490NZ |

490Z |

498Z |

4102Z |

4105Z |

4108Z |

|

Type |

Direct Injection, Water-cooling, Four Stroke |

||||||||||

|

Intake Type |

Naturally Aspirated |

Turbo-charging |

|||||||||

|

Bore*Stroke(mm*mm) |

98*105 |

102*118 |

105*118 |

108*118 |

85*100 |

90*100 |

90*105 |

98*105 |

102*118 |

105*118 |

108*118 |

|

Cylinder No. |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

4 |

|

Displacement (L) |

3.168 |

3.857 |

4.087 |

4.324 |

2.27 |

2.54 |

2.67 |

3.168 |

3.857 |

4.087 |

4.324 |

|

Rated Power/ Speed(kW/r/min) |

54/3000 |

62/3000 |

67/3000 |

73/3000 |

44/3000 |

50/3000 |

55/3000 |

60/3000 |

73/3000 |

75/3000 |

83/3000 |

|

Horse Power |

73 |

85 |

91 |

99 |

60 |

68 |

75 |

81 |

99 |

102 |

113 |

|

Power Coverage(kW) |

≤75 |

≤100 |

≤100 |

≤100 |

≤55 |

≤55 |

≤55 |

≤75 |

≤100 |

≤100 |

≤100 |

P2C

TECHNICAL DATA / DATOS TÉCNICOS 60Hz n=3500 1/min

|

MODEL |

Power |

l/min |

Q=DELIVERY |

DN |

|||||||||||||||||||

|

0 |

40 |

50 |

60 |

70 |

80 |

90 |

100 |

110 |

120 |

140 |

160 |

180 |

200 |

250 |

300 |

350 |

400 |

450 |

|||||

|

kw |

hp |

m³/h |

0 |

2.4 |

3 |

3.6 |

4.2 |

4.8 |

5.4 |

6 |

6.6 |

7.2 |

8.4 |

9.6 |

10.8 |

12 |

15 |

18 |

21 |

24 |

27 |

mm |

|

|

25-140/11 |

1.1 |

1.5 |

Head H(m) |

54 |

47.5 |

44.5 |

41 |

37 |

33 |

28 |

22 |

|

|

|

|

|

|

|

|

|

|

|

32x25 |

|

25-140/15 |

1.5 |

2 |

67 |

60 |

57 |

54 |

50 |

45 |

40 |

32 |

|

|

|

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/11 |

1.1 |

1.5 |

47 |

44 |

42 |

40 |

38 |

35 |

33 |

30 |

27 |

24 |

|

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/15 |

1.5 |

2 |

58 |

54 |

53 |

51 |

49 |

47 |

45 |

43 |

40 |

37 |

30 |

|

|

|

|

|

|

|

|

32x25 |

|

|

25-160/22 |

2.2 |

3 |

68 |

64.5 |

63 |

62 |

60 |

58 |

56 |

54 |

51 |

48 |

41 |

32 |

|

|

|

|

|

|

|

32x25 |

|

|

32-200/30 |

3 |

4 |

70 |

|

|

|

|

63 |

62 |

60.5 |

59 |

57 |

55 |

52 |

49.5 |

46.5 |

36 |

|

|

|

|

40x32 |

|

|

32-200/40 |

4 |

5.5 |

85 |

|

|

|

|

77 |

76 |

75 |

74 |

72 |

69 |

66 |

62 |

58 |

49 |

|

|

|

|

40x32 |

|

|

32-210/55 |

5.5 |

7.5 |

94 |

|

|

|

|

91 |

90 |

89 |

87 |

85 |

83 |

79 |

75 |

70 |

56 |

|

|

|

|

50x32 |

|

|

32-210/75 |

7.5 |

10 |

112 |

|

|

|

|

110 |

109 |

108 |

107 |

105 |

102 |

99 |

94 |

89 |

74 |

|

|

|

|

50x32 |

|

|

40-210/55 |

5.5 |

7.5 |

94 |

|

|

|

|

91 |

90 |

89 |

87 |

85 |

83 |

79 |

75 |

70 |

56 |

|

|

|

|

50x40 |

|

|

40-210/75 |

7.5 |

10 |

112 |

|

|

|

|

110 |

109 |

108 |

107 |

105 |

102 |

99 |

94 |

89 |

74 |

|

|

|

|

50x40 |

|

|

50-180/40 |

4 |

5.5 |

62 |

|

|

|

|

59 |

58 |

57 |

56 |

55 |

55 |

50 |

48 |

44 |

36 |

31 |

23 |

|

|

50x50 |

|

|

50-180/55 |

5.5 |

7.5 |

72 |

|

|

|

|

69 |

68 |

67 |

66 |

65 |

65 |

60 |

58 |

54 |

46 |

41 |

33 |

|

|

50x50 |

|

|

50-180/75 |

7.5 |

10 |

84 |

|

|

|

|

81 |

80 |

79 |

78 |

76 |

75 |

72 |

72 |

66 |

58 |

53 |

45 |

|

|

50x50 |

|

|

40-200/92 |

9.2 |

12.5 |

97 |

|

|

|

|

|

|

|

|

|

91.5 |

91 |

90 |

88 |

85 |

80 |

74 |

68 |

61 |

50x40 |

|

|

40-200/110 |

11 |

15 |

105 |

|

|

|

|

|

|

|

|

|

100 |

99 |

98 |

97 |

93 |

88 |

83 |

76 |

69 |

50x40 |

|

|

50-200/92 |

9.2 |

12.5 |

97 |

|

|

|

|

|

|

|

|

|

91.5 |

91 |

90 |

88 |

85 |

80 |

74 |

68 |

61 |

50x50 |

|

|

50-200/110 |

11 |

15 |

105 |

|

|

|

|

|

|

|

|

|

100 |

99 |

98 |

97 |

93 |

88 |

83 |

76 |

69 |

50x50 |

|

|

40-250/130 |

13 |

17.5 |

120 |

|

|

|

|

|

|

|

|

|

114 |

113 |

112 |

110 |

107 |

103 |

98 |

91 |

82 |

50x40 |

|

|

40-250/150 |

15 |

20 |

130 |

|

|

|

|

|

|

|

|

|

124 |

123 |

122 |

120 |

117 |

113 |

108 |

102 |

92 |

50x40 |

|

|

40-250/185 |

18.5 |

25 |

145 |

|

|

|

|

|

|

|

|

|

139 |

138 |

137 |

136 |

131 |

126 |

121 |

114 |

107 |

50x40 |

|

|

40-250/220 |

22 |

30 |

160 |

|

|

|

|

|

|

|

|

|

155 |

153 |

152 |

151 |

146 |

141 |

135 |

130 |

122 |

50x40 |

|

|

50-250/130 |

13 |

17.5 |

120 |

|

|

|

|

|

|

|

|

|

114 |

113 |

112 |

110 |

107 |

103 |

98 |

91 |

82 |

50x50 |

|

|

50-250/150 |

15 |

20 |

130 |

|

|

|

|

|

|

|

|

|

124 |

123 |

122 |

120 |

117 |

113 |

108 |

102 |

92 |

50x50 |

|

|

50-250/185 |

18.5 |

25 |

145 |

|

|

|

|

|

|

|

|

|

139 |

138 |

137 |

136 |

131 |

126 |

121 |

114 |

107 |

50x50 |

|

|

50-250/220 |

22 |

30 |

160 |

|

|

|

|

|

|

|

|

|

155 |

153 |

152 |

151 |

146 |

141 |

135 |

130 |

122 |

50x50 |

|

|

No. |

Description |

Material |

No. |

Description |

Material |

No. |

Description |

Material |

|

1 |

Pump Case |

Cast iron |

9 |

Wound Stator/Rotor |

Silicon Steel/Copper |

17 |

Terminal Box |

Aluminum |

|

2 |

Impeller |

Brass |

10 |

Motor Case |

Aluminum |

18 |

Terminal Board |

Plastic |

|

3 |

Mechanical Seal |

SiC/Carbon/SS304 |

11 |

Support Foot |

Plastic |

19 |

Impeller Key |

Iron |

|

4 |

O-ring |

Rubber |

12 |

Back Cover |

Cast iron |

20 |

Water Deflector |

Rubber |

|

5 |

Connection |

Cast iron |

13 |

Reinforced Seal |

Rubber |

21 |

Release Valve |

Brass |

|

6 |

Reinforced Seal |

Rubber |

14 |

Fan Cover |

Aluminum |

22 |

Diffuser |

Cast iron |

|

7 |

Shaft |

SS304/45# Steel |

15 |

Fan |

Plastic |

23 |

Impeller Nut |

Galvanizated Steel |

|

8 |

Bearing |

Ball Bearing |

16 |

Through Bolt |

Steel |

24 |

Connection Bolt |

Steel |

Spare Parts

Packaging & Shipping

Our Exhibition

Certifications